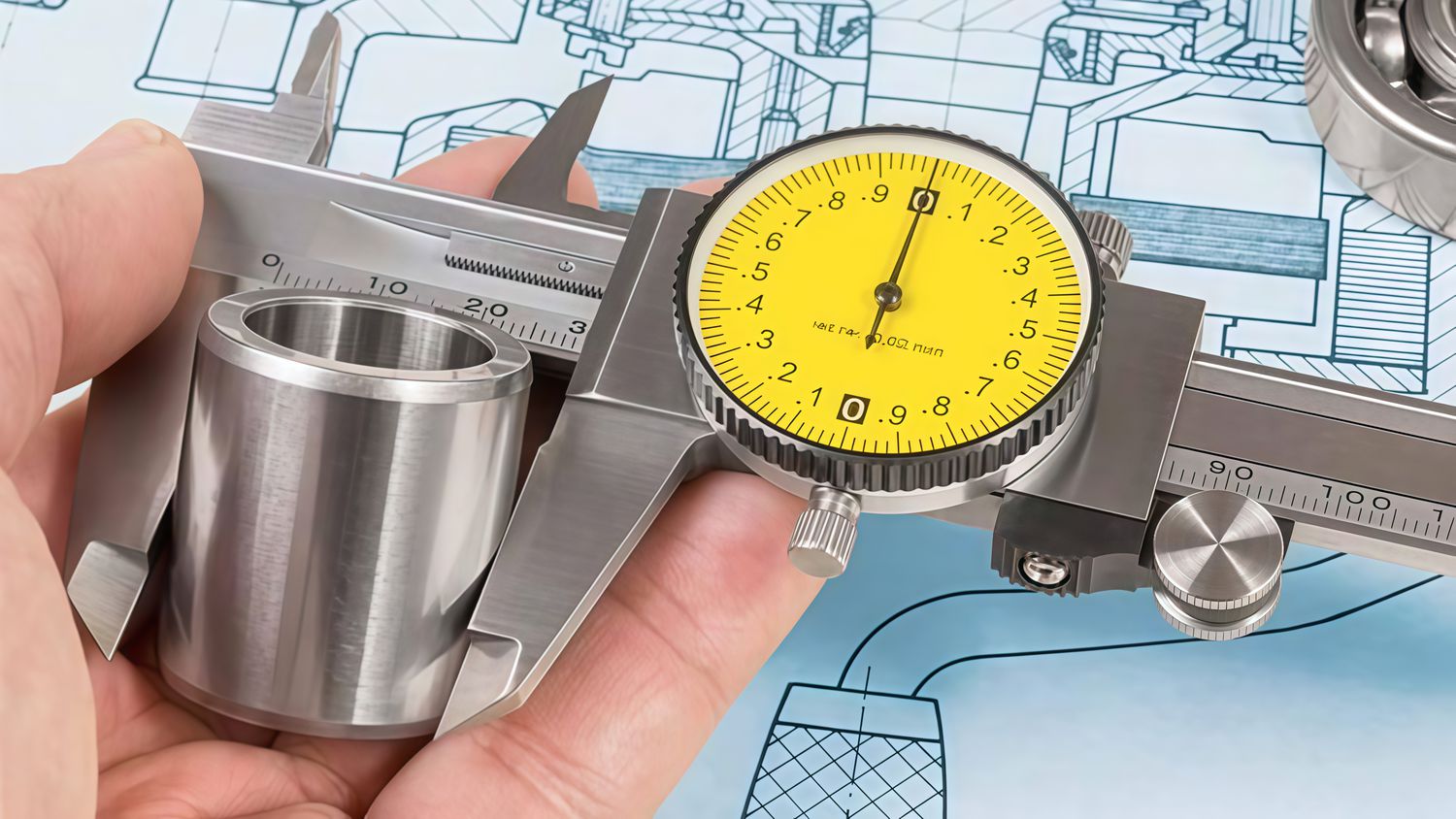

Dial caliper

Why dial calipers remain popular in the electronic era

Today, in many mechanical workshops, digital calipers have become a common choice thanks to their ability to display results directly. Yet dial calipers still hold a solid place. Why is that? A dial caliper does not depend on batteries, is not affected by a dim screen in cold conditions, and does not lose data due to moisture. These reasons make it a reasonable and practical tool worth considering.

The feeling of watching the needle rotate and move step by step to read a value remains familiar to many engineers. It is similar to how many people still prefer mechanical watches even when they own smartphones. It is not only about durability, but also about an intuitive experience and the peace of mind while working.

Key advantages of using dial calipers in mechanical workshops

One of the greatest strengths of dial calipers is their long-term durability. In mass production environments, tools may face minor collisions or environmental effects, yet dial calipers still maintain accuracy within acceptable limits. Workers can quickly check a product without worrying about replacing or charging batteries.

Another advantage is the readability. The dial’s needle allows users to detect deviations more sensitively than digital numbers. With just a quick glance, one can see whether the needle has shifted off the mark. This is especially useful for spotting small variations during repeated measurements. Simplicity is also a benefit. There are no buttons, no complicated settings—just open the caliper, measure, and read the result.

Typical applications of dial calipers

In a machining workshop, dial calipers are often used to measure the outer diameter of shafts or bearings. The repeated nature of these tasks makes the tool quick and reliable.

When it comes to checking inner diameters, the compact jaws of the caliper also make the job convenient without requiring more complex equipment.

During mass production, quick checks with dial calipers can determine whether a production line runs smoothly. Engineers do not always bring out a micrometer or a 3D measuring machine for inspection. A quick and straightforward measurement is enough to confirm that a product meets specifications. In such cases, a dial caliper is sufficient and sometimes even more effective than modern devices.

Read more related articles:

Do you understand the IP index on calipers and electronic micrometers?

Not everyone knows the application of calipers

User habits and common concerns

Beginners often ask whether they need a dial caliper when digital calipers are already widespread. The answer depends on the working environment. If the workshop has a lot of metal dust, oil, or high humidity, a dial caliper proves significantly more durable.

Another concern is accuracy. Some believe digital calipers are more precise, but in reality, dial calipers from reputable brands still ensure errors only within a few hundredths of a millimeter, which fully meets the requirements of most machining tasks. Durability is also a topic of interest. Many users report that a single dial caliper can last for decades as long as it is properly maintained and calibrated periodically.

Those with long-term experience tend to care more about brand reputation and spare parts availability. Common questions include whether the glass can be replaced if scratched, whether replacement needles are available, or whether regular calibration is complicated. These concerns reflect the long-lasting bond users have with dial calipers, treating them as durable tools closely tied to daily work.

How to choose the right dial caliper for your needs

It is not always necessary to choose the most expensive caliper. For those working in mass production where moderate accuracy is sufficient, a standard model at an affordable price is enough. However, in fields that demand higher accuracy, such as mold manufacturing or medical equipment, investing in a caliper from a reputable brand with fine graduations and high stability is essential.

Measuring range is also an important factor. Most routine tasks only require a 150 mm caliper, but for frequent measurement of larger parts, 200 mm or 300 mm models are more suitable. At EMIN, models such as the Mitutoyo 505-730 (150 mm) or Mitutoyo 505-745 (300 mm) are commonly chosen by workshops for their durability and stability. Budget, of course, also plays a role, but experience shows that a good dial caliper can last for decades, making it a long-term investment worth considering.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-